At present, the competition in the new energy vehicle market is becoming increasingly fierce. With Tesla's price reduction, BYD's open letter asking suppliers to reduce prices and other events, it can be expected that the subsequent competition will enter a more heated stage.

If automobile companies want to win a place in the highly competitive new energy vehicle market, they can only rely on high-quality products with high added value and leading technology. While the major car companies continue to promote technological innovation, they also focus on the optimization of parts costs in order to enhance product strength and enhance the competitiveness of enterprises. Among them, high-voltage wiring harnesses, as highly valuable components in pure electric vehicles, naturally become the key to cost optimization.

1. Introduction to high voltage wiring harness

The high voltage wiring harness connects the various components of the high voltage system, as the medium of high voltage power transmission, and is the main carrier of power output on the electric vehicle, mainly used for transmitting electric energy and shielding external signal interference.

High voltage harness has the characteristics of high voltage, high current, high protection level and anti-electromagnetic interference, which is the neural network of pure electric vehicle high voltage system, and is the key component of vehicle performance and safety.

High voltage wiring harnesses of pure electric vehicles are generally divided into power battery high voltage wiring harnesses, motor controller high voltage wiring harnesses, fast charging socket wiring harnesses, slow charging socket wiring harnesses, air conditioning system wiring harnesses and charging high voltage wiring harnesses, among which charging high voltage wiring harnesses are the wiring harnesses connecting high voltage distribution boxes to vehicle chargers, air conditioning compressors and power battery pack heaters.

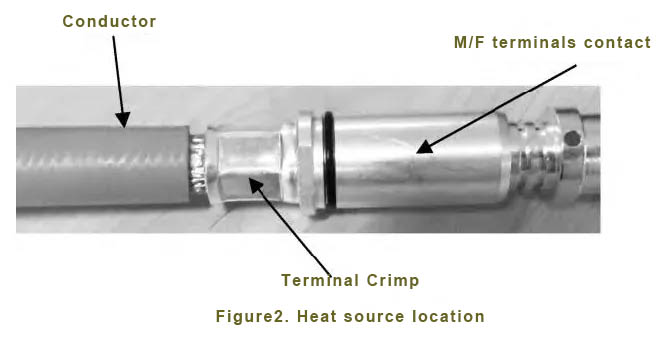

The high-voltage wire harness mainly consists of high-voltage connectors, high-voltage cables, cladding materials (tape, heat shrink pipe, bellows, wear-resistant self-winding pipe, etc.), and protection plates. The production process of high voltage wire harness mainly includes cutting wire, preassembly of accessories, terminal crimping/ultrasonic welding, shielding crimping, wire harness assembly and electrical inspection.

2. Cost composition of high voltage wiring harness

The cost of high voltage wiring harness consists of material cost, processing fee, packaging and transportation fee and management fee.

The material cost of high voltage wiring harness is mainly determined by the technical scheme of wiring harness, and the processing cost includes labor cost, power cost, equipment depreciation cost and low value consumable goods.

The following is the cost composition ratio of the high-voltage wiring harness of a certain vehicle (see Figure 1) and the cost composition ratio of the high-voltage wiring harness material (see Figure 2). The cost of the high-voltage wiring harness material accounts for about 73.8% of the total cost of the wiring harness. It is necessary to reduce the cost of high voltage wiring harness by optimizing design and production process.

|

|

| Figure 1 Proportion of the cost composition of high voltage wiring harness |

Figure 2. Material cost composition ratio of high voltage wiring harness |

3 High voltage wire harness cost reduction research

There are three main methods to reduce the cost of enterprises in the automotive industry, including scale, supplier collaboration and technology cost reduction, among which technology cost reduction is the most effective and sustainable way to reduce costs.

At present, there are three main methods of cost reduction: cost benchmarking, management technology and technical means.

Under normal circumstances, the method of technical means includes reducing redundant functions, improving the localization rate and standardizing the platform.

In the pure electric vehicle high voltage wiring harness cost reduction activities, this research mainly uses technical means to optimize the cost of high voltage wiring harness from the following aspects.

3.1 High-voltage system architecture optimization

On pure electric vehicles, High-voltage components include power battery, 3-in-1 (motor controller + drive motor + subtraction), PDU (high-voltage distribution box), ECP (electric compressor), 2-in-1 (IPS=OBC+DC-DC), HVH (battery heating), PTC (occupant heating), slow charger (ACInlet), and fast charger (DC) Inlet, high pressure harness, etc. These components constitute the high pressure system of the vehicle. The high voltage system architecture of pure electric vehicles is optimized, which can greatly reduce the number of connectors used and redundant high voltage wiring harnesses. Taking the high voltage system architecture optimization of a project as an example, before optimization, PDUs in the high voltage wiring harness system architecture only exist as power distribution function modules, and there is no vehicle functional performance related module, as shown in Figure 3.

FIG. 3 Architecture diagram of high voltage system before optimization

FIG. 3 Architecture diagram of high voltage system before optimization

The independence of PDUs increases the number of transfers in HV wiring harness systems. The two functions of HVH and PTC are similar, resulting in an increase in the number of high-voltage harness circuits. The fast and slow charging sockets are arranged on the left and right rear side, and are too far away from the electrical interface (the battery fast charging interface is in the front, and the charger slow charging interface is in the front cabin), so that the high voltage wiring harness length is too long.

After research and analysis, the functional electrical components are only used for connecting the function of copper bar and power protection function of the fuse, and it is easy to integrate with other electrical appliances. The PDU and IPU integration can eliminate a high voltage distribution box assembly, while saving a set of motor controller wiring harnesses (approximately 1.5m of 50mm2 wire and two pairs of φ8mm terminal connectors), which can bring significant cost reduction. HVH and PTC have similar functions, and when the two functions are combined, the high-voltage wiring harness can reduce one loop (about 1.5m of 3mm2 wire and two pairs of 2.8mm blade width terminal connectors), and the high-voltage system architecture is optimized, as shown in Figure 4.

FIG. 4 Architecture diagram of high voltage system after optimization

Through this high voltage system architecture optimization, four high voltage connectors and two high voltage wiring harnesses are reduced, and the cost of high voltage wiring harnesses can be reduced by about 730 yuan.

3.2 Optimization of high-voltage wiring harness layout

The high-voltage wiring harness layout needs to be continuously optimized according to the model, and the use of high-voltage cables can be reduced after optimization to further reduce costs. Taking the layout optimization of the fast and slow charging ports of a certain vehicle as an example, before optimization, the fast and slow charging ports were arranged in the left and right rear side, and the length of the fast and slow charging harnesses was too long, among which the length of the slow charging harnesses was about 4.5m and the length of the fast charging harnesses was about 4m, resulting in high cost of the fast and slow charging high-voltage harnesses. After optimization, the charging port is arranged at the left and right sub-boards, close to the charger and battery pack, to reduce the length of high voltage wiring harness. The layout diagram before and after optimization is shown in Figure 5 and 6. The cost can be reduced by about 260 yuan through this high-voltage wiring harness layout optimization.

Figure 5 Layout diagram of fast and slow charging before optimization

Figure 6 Layout diagram of fast and slow charging after optimization

3.3 High voltage harness material optimization

High voltage wire harness cost composition, material cost accounted for the highest, the current status of the analysis, the current high voltage wire harness material optimization direction mainly for charging socket integrated design, high voltage connector localization, high voltage cable diameter optimization and material one-to-many optional optimization.

3.4 Integrated design optimization of charging socket

Before optimization, the charging socket is designed as a split type with high cost. Before optimization, the split type charging socket is shown in Figure 7, including a fast charging socket and a slow charging socket. Through the development and design of the charging socket according to the platform scheme, the main structure of the charging socket of all projects is solidified to minimize the development cost. After optimization, the integrated charging socket is shown in Figure 8. Through this optimization, a set of flange molds can be reduced and the high voltage wiring harness assembly cost can be reduced by about 8 yuan.

Figure 7 Split charging socket before optimization

Figure 8 Integrated charging socket after optimization

3.5 High voltage connector localization

In recent years, the high voltage connector industry has developed rapidly, and a number of excellent domestic high voltage connector brand suppliers have emerged. Before optimization, the main use of TE and other foreign brands of high-voltage connectors, through the localization of high-voltage connectors continuous optimization, with domestic brands such as Luxshare, Ebusbar and other localization replacement, the cost reduction of high-voltage connectors is of great significance, as shown in Table 1 below for the high-voltage connector localization demonstration case.

Table 1 High-voltage connector localization demonstration case

| Original Brand |

Original P/N |

Equivalent Brand |

Equivalent P/N |

| TE |

1-2347299-1 |

Ebusbar |

123-0500-0002 |

| TE |

2-2356258-2 |

Luxshare |

HVP800022CVA11 |

3.6 High voltage cable diameter optimization

Through the interpretation of regulations, benchmarking and statistical cloud big data measures to optimize the cable diameter of high voltage lines. For specific high-voltage cables, it is often possible to optimize the section, temperature requirements, flexibility and shielding effect to avoid excessive size and excessive components. Taking fast-charging high-voltage cables as an example, the optimized front-line cable diameter is 70mm2, and the optimized cable diameter is 50mm2, which can meet the actual charging requirements.

3.7 One-to-many optional optimization of materials

The one-to-many high-voltage wiring harness materials can fully mobilize the enthusiasm of tier1 suppliers and make use of tier1 suppliers' own supply chain advantages to choose the best cost plan for supply. Taking high-voltage cables with relatively high material costs as an example, the current main specifications of high-voltage cables are developed according to the one-to-many idea according to the high-voltage cable standard, and each specification harness factory has multiple specifications to choose from, of which the specific application wire of each loop needs to be confirmed according to the actual load of the vehicle. Through continuous optimization design, many materials can be selected one-to-many at present, and Table 2 below is only a one-to-many example of some materials.

Table 2 One-to-many examples of materials

| Materials |

Supplier |

P/N |

| 50mm² Silicone shielded wire |

Kolop |

FHLR2GCB2G_50 |

| Hua Cheng |

FHLR2GCB2G_50 |

| Lenny |

FHLR2GCB2G_50 |

| Beijing Fox |

FHLR2GCB2G_50 |

3.8 Platform and standardized design

The platform and standardized design from the whole vehicle wiring harness principle and raw materials can greatly shorten the development cycle of the whole vehicle wiring harness design stage, reduce repeated verification tests, and reduce the wiring harness cost. Through the continuous platforming and standardization of wire harness materials, the types of materials are reduced, and the quantity of a single material can play a large-scale effect, which is of great significance for material cost reduction. Through research and analysis, the platform and standardization of secondary materials (connectors, cables, accessories, etc.) can greatly reduce the material cost of high voltage wire harness. The following is an example of the high voltage plug-in platform. Under the condition of the same electrical performance, the plate end connectors of different brands (TE and Luxshare) can be installed in the opening size of the aluminum alloy panel of the battery pack at the same time, as shown in Figure 9, 10 and 11. This platform design has strong versatility.

Figure 9 Holes on the aluminum alloy panel of the battery pack

Figure 10 Board end of TE brand HVP2P800

Figure 11 HVP2P800 board end of Luxshare brand

4. Summary and prospect

Due to the characteristics of high voltage, high current and large number of wire diameters, high voltage wire harnesses of pure electric vehicles are faced with challenges such as wiring, safety, shielding, weight and cost. As a high-value pure electric vehicle component, high voltage wire harness can contribute to the cost reduction of the whole vehicle through continuous cost optimization research. Cost reduction work is a continuous optimization and continuous activity, and the follow-up needs to be continuously optimized to minimize the cost of the vehicle and provide customers with more competitive products.

Aichie Tech provides auto wiring harness , high voltage ev cable assembly and low -voltage auto wiring harness around the world. It has introduced new production equipment, which greatly improves the quality and efficiency of production. Customers are widely distributed in Europe and North America. Production employees and experienced engineering teams and sales teams serve our customers; please contact us now! We will provide you with competitive prices!

E: sales03@aichie.com

WeChat: 180 2750 2150

Tel: +86 180 2750 2150